SPE/IADC MPD & UBO 2022 Conference & Exhibition

September 26, 2022Join me in Kuala Lumpur for my presentation during the Session “Technology Advances in Managed Pressure Operations” at the SPE/IADC Managed Pressure Drilling & Underbalanced Operations 2022 Conference & Exhibition which will take place on 27-28 September in Kuala Lumpur, Malaysia. For complete program and registration please visit:

https://www.iadc.org/event/2022-spe-iadc-mpd-and-uo-conference-exhibition/#program

Hope to see you there!

RT-IME shown at Gibson Reports

August 13, 2021Join us on the Gibson Reports MPD Event

June 12, 2021Join us on Wednesday the 16th of June for Gibson Reports Virtual MPD event where we will unveil our solution that bridges the influx management planning and operations gap – the Real-Time IME.

Our very own Martin Culen will speaking in the event around 11am Houston time.

Click here to sigh up for the Gibson Report – Virtual MPD Event June 16th

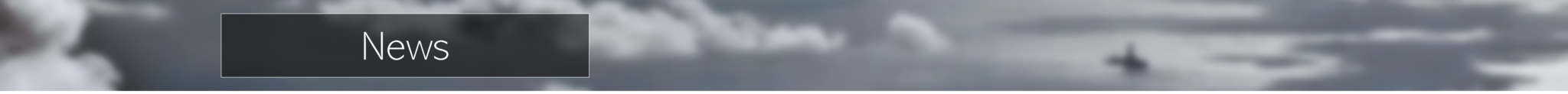

First milestone of R&D project supported by Innovation Norway

June 4, 2021Our team has been working hard on an exciting digital twin R&D initiative that has been made possible through financial support by Innovation Norway.

The innovation of the project is simulator technology that enables the same hydraulics engine to be used effectively through all phases of the complete life-cycle of well construction, from the initial planning to real-time drilling advisory and control. The primary objective is to allow the handling of hydraulics model parameters in one place, cascading them through all of the phases.

Traditionally, planning, training, advisory and operational control tools each employ different calculation methodologies and solvers. Furthermore, they have been developed on different platforms, each operating in isolation from the other. This introduces large opportunities for input error, deviation from expected results, and data re-entry end-user frustration.

This project uses new results from research on fast multiphase models combined with the latest improvements of cloud-based technology to develop a hydraulics engine that can be used for effective simulations of all time-scales from steady-state to full transient simulations. This enables the same hydraulics engine to be used for effective simulations on the scale of hours and days of drilling in the planning phase, to realistic simulator-based training on well control incidents with compressible gas transport on a minutes scale, to full transient simulations with high-frequency pressure wave transients for controller testing in the seconds scale.

We have now reached the first milestone of the project, and are ready to release the first module of the simulator, named LeidarPlan. We are excited about what we’ve developed so far, and will have more news very soon.

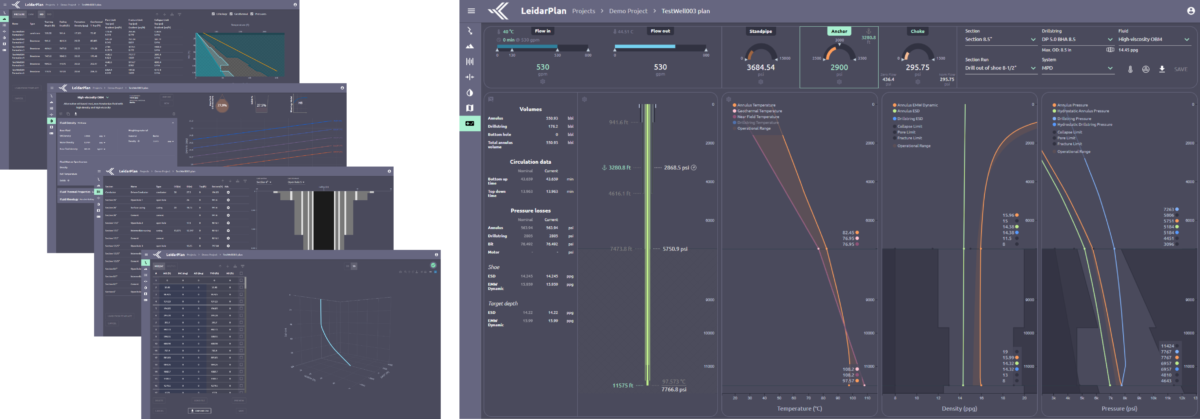

Aberdeen Drilling School to Exclusively Use Kelda’s Hydraulic Engine

March 25, 2021Aberdeen Drilling School (ADS) and Kelda Dynamics have entered into an agreement whereby Kelda’s dynamic hydraulic engine will be used exclusively in ADS drilling and well control simulators.

“We have been using Kelda’s multiphase hydraulics engine in our advanced training simulators in Oiltec since 2016, and have been very happy with its performance and reliability. Kelda’s shared vision for cloud-based solutions fits very well with our plans to provide cloud-based training to our international clients. ” said, Jason Grant, Managing Director of ADS.

Glenn-Ole Kaasa, CEO of Kelda, adds ” We are very pleased to be working with ADS on their new initiatives. It’s an honor to be chosen as exclusive supplier to a world-renowned training organization. The ADS team is very forward thinking and we’re excited to be working with them. It’s extremely rewarding to experience how the drilling industry now adapts our technology further, to improve drilling efficiency and enhance operational safety.”

The hydraulic simulator engine will be rolled out to ADS and RelyOn training centers around the globe as well as planned cloud-based training courses.

Aberdeen Drilling School Ltd, part of the RelyOn Nutec group and globally recognized for its advanced drilling, well engineering and well control training. From our RelyOn Nutec Copenhagen headquarter and 33 sites around the world, we serve +10,000 companies every year, from the sole employee contractor to some of the biggest companies in the high-risk industries across the world.

Kelda Dynamics has a unique competence in drilling technology, delivering fit-for-purpose solutions for the drilling industry. Our dynamic hydraulic model is a core element of our expertise and of many Kelda’s market leading technology products. It is being continuously developed, based on new research, data from newly drilled wells and feedback from customers.

Contact for further information:

Jason Grant: jgrant@aberdeendrilling.com

Martin Culen: martin@kelda.no

CB explains: The IME approach to handling influxes with MPD

March 12, 2021For surface backpressure Managed Pressure Drilling (MPD) drilling operations, it is possible to circulate minor influxes using the MPD equipment, without resorting to conventional “well control” with a closed Blow Out Preventer (BOP).

Still, the MPD equipment has a significantly lower pressure rating than the blow-out preventer, and a less rigorous testing regime than well control equipment. Due to this, the decision of circulating out an influx through MPD equipment should not be taken lightly.

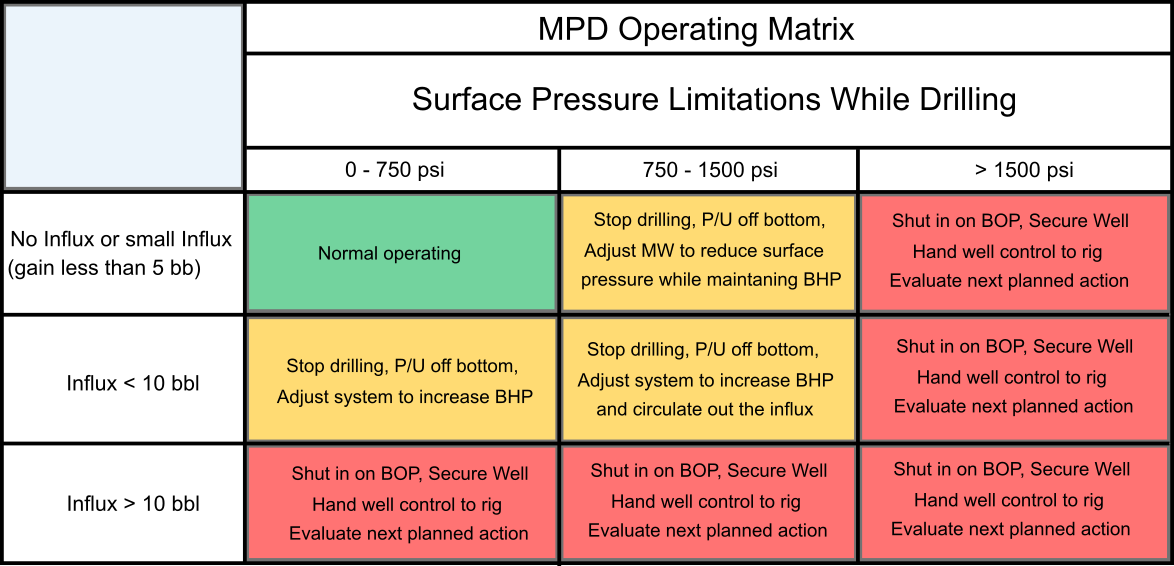

Numerous guidelines and tools such as the “MPD Operating Matrix” and “Influx Management Envelope” are at the core of decision making related to dealing with minor influxes using the MPD equipment.

MPD Operating matrix

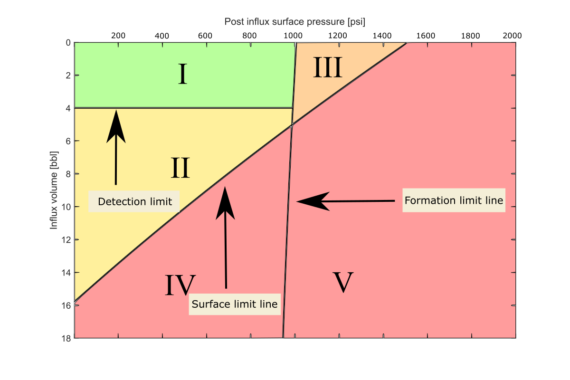

To help with this decision making, the Bureau of Safety and Environmental Enforcement (BSEE) released guidelines for drilling operations in the Gulf of Mexico in 2008. One of the recommendations was to develop a “MPD Operating Matrix” (also known as the “MPD Well Control Matrix (WCM)”. The “MPD Operating Matrix” is well known and used extensively on most MPD operations worldwide. An example of an MPD Operating Matrix is shown below.

The MPD Operating Matrix aims to answer the following question:

“At my current surface pressure, and having taken an influx of a known size, can this influx be circulated through the MPD equipment, or should the BOP be closed, and conventional well control operations commence?”

MPD Operating Matrix. Are you OK to circulate your influx using MPD equipment or should BOP be closed, and rig commences well control operations? Note that the pressures and volumes shown in this matrix are for illustration only. Actual values should be the result of depth specific calculations

The limits in the Operating Matrix are usually given by the surface pressure limit, expected surface pressure in operation, and typical influx detection algorithm limitations. The MPD Operating Matrix is designed to provide post influx guidance. Once an influx has been suppressed, the calculated or measured influx volume and resultant surface back pressure is cross referenced to the matrix to determine the next recommended actions (yellow or red zones).

Isn’t this good enough?

The matrix provides good guidance; however it has one serious drawback: If the influx volume and new surface back pressure recommends to circulate the influx using MPD equipment (yellow or green zone), it typically does not consider that if the influx is gas, surface pressure will have to be increased when the influx is circulated to the surface. Increased surface back pressure during circulation is required to maintain bottomhole pressure constant and avoiding a secondary influx.

In other words, it might say you can circulate using MPD equipment, but increasing back pressure during the circulation could push closer and closer to the surface limit, requiring a transition to the BOP and conventional well control practices in the middle of what is already a complex operation.

This issue was pointed out independently in the papers:

“The MPD Well Control Matrix; What is Actually Happening” by Mir Rajabi et. al. in 2014

“Evolution of the MPD Operations Matrix: The Influx Management Envelope” by Culen et. al. in 2016.

The solution to this is simple:

The “Influx Management Envelope” or IME for short.

IME?

The overall “look” of an IME is deceptively simple and similar to a MPD Operating Matrix, but the question it answers is the key to its improvement over the Operating Matrix.

Below is the original question from above, with the key differences for the IME highlighted in bold:

“At my current surface pressure and having just taken an influx of a known size. At my current depth, can this influx be circulated through the MPD equipment all the way to the surface, or should the BOP be closed, and conventional well control operations commence?”

As it happens, knowing “post-influx” surface pressure and influx volume right after the influx is taken, it is possible to predict what the peak “future” surface pressure will be.

If one were to simulate multiple combinations of post influx pressure and influx volume including circulation to the surface, an interesting finding appears:

There are multiple combinations of post-influx pressure and influx volume that will result in the imposed surface pressure limit. If one were to plot all these combinations it usually takes the form of a near straight line.

Superimposing a line like this, called the “surface limit”, on the conventional MPD Operating Matrix (assuming that the axis can be treated as “continuous”) and the same surface limit of 1500psi looks like this:

The IME has a “surface limit” line that considers the increase in pressure when the influx is circulated to the surface. In many cases there is a significant part of the MPD Operating Matrix outside the IME surface limit line. Influxes in this region can exceed surface pressure limits when circulated with MPD equipment. There is often also an “unexploited” region in the IME vs the Operating Matrix at low post influx pressure.

The above clearly illustrates that considering the required increase in pressure when circulating the influx to the surface, Influx Volume and Surface Pressure should not be considered “independent” when considering the criticality of an influx. Whether an influx can be circulated to the surface with MPD equipment while considering the required additional surface pressure is a combination of the two variables for a given well.

Does this mean we should stop doing a “Operating Matrix”?

No, not necessarily. But it does mean that in the example above, ideally the Operating matrix should have a surface limit pressure/influx volume limit that makes it fit “inside” the IME surface limit. In other words, some calculation should be performed when using the Operating matrix. Doing this one can ensure that the lower right yellow corner represents a volume/pressure combination that could be circulated to surface with MPD equipment for a given well, without violating the surface limit.

An Operating matrix like this would be perfectly fine, but often having a relatively small window for influx circulation, due to neglecting a large region where the influx could be safely circulated over MPD equipment if considering the IME.

To remedy the issue of the MPD Operating matrix being outside the IME surface limit line, a calculation based MPD Operating matrix can be made. This would consider the required extra surface pressure when circulating the influx to surface. When this is performed, the MPD operating matrix often become rather “small”, and there are large regions outside of it where the influx could be safely circulated if one where to consider the IME surface limit.

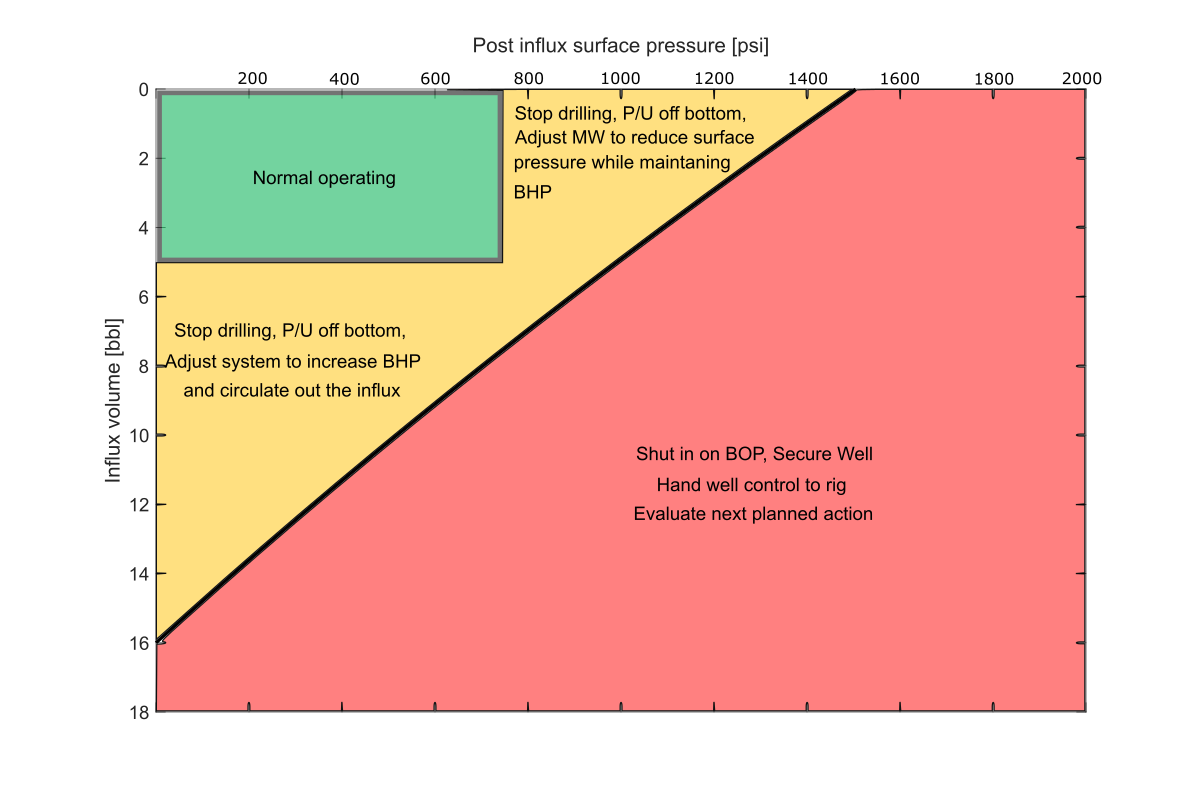

How do I use an IME?

Using an IME operationally is as simple as using the MPD Operating Matrix. Below is the IME for the case above, where the regions outside the Operating Matrix is exploited.

After an influx is taken, a point is plotted for the post influx pressure and influx volume. The region this point falls in determines subsequent actions.

What about my formation limits?

In operation, the surface equipment pressure rating is not the only pressure limit one should consider. In most cases there is also a formation pressure limit. Using the same approach as above, one will find that there is also a combination of post influx pressure and influx volume that will exactly hit my formation pressure limit. The pressure and volume combinations that hit the formation limit pressure also forms a near straight line, the “formation limit line”.

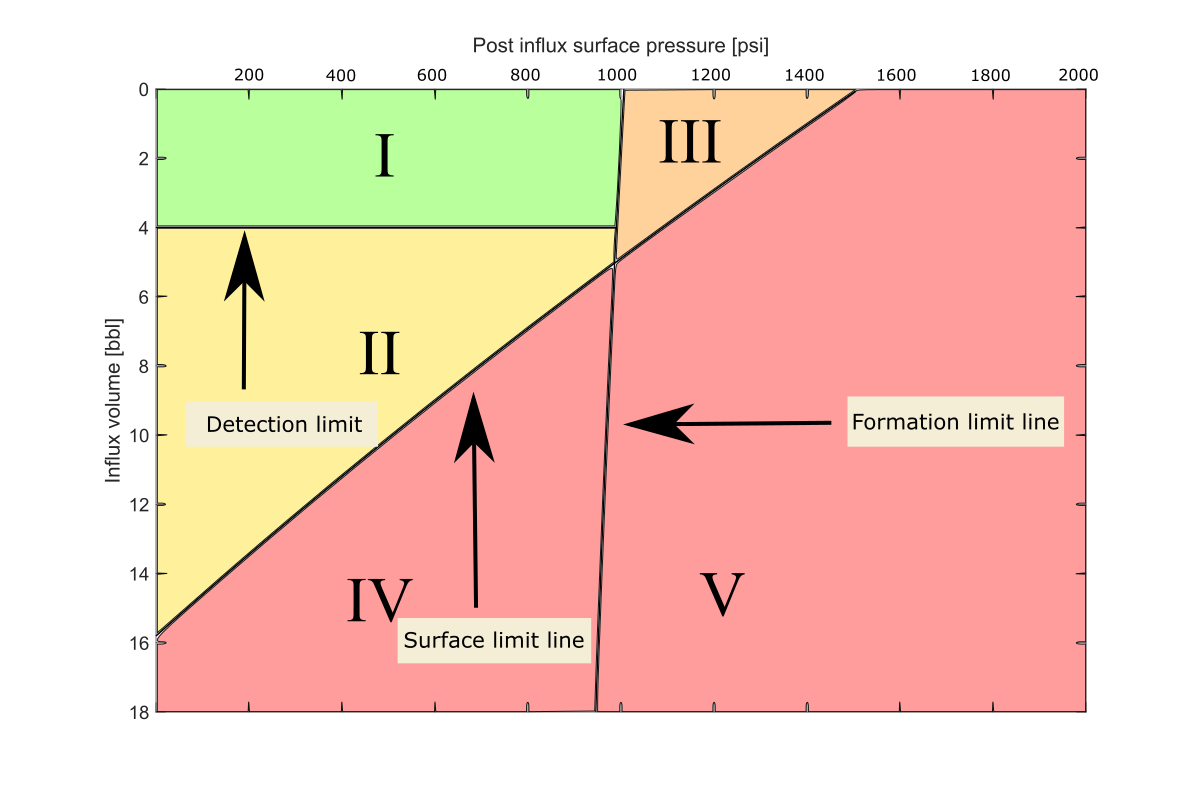

Bringing it all together

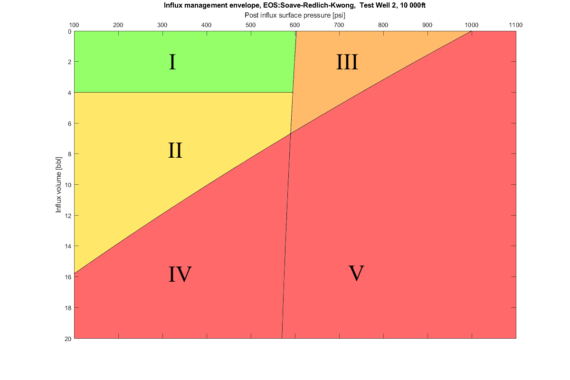

Considering both a surface pressure limit, formation pressure limit, and mapping out all the combinations of “post influx pressure” and influx volume that hit these, an IME can be constructed. An example of a full IME can be seen below.

I. Below influx detection limit, no influx is detected, and operation continues as normal.

II. Influx detected and suppressed. Combinations of post-influx surface pressure and kick volume in this region will not exceed the specified surface-pressure limit when circulated to the surface and can be circulated out using the MPD equipment.

III. Influx/ post-influx pressure combinations in this region will exceed the specified formation pressure limit when circulated to the surface. The criticality of this depends on how the weak-point limit has been found, and the likelihood of an underground blowout if the limit is exceeded.

IV. Combinations of post-influx pressure and kick volume in this region will exceed the specified maximum surface pressure when circulated out, but the kick will not violate the weak-point pressure limit. The kick can be circulated with the MPD equipment initially, but then handed over to conventional well control once the influx has reached a pre-determined depth/ surface pressure.

V. Combinations of post-influx pressure and kick volume in this region will exceed both the MPD surface-pressure limit and violate the weak-point pressure limit. A kick in this region might prove challenging, even when doing conventional well control.

This seems like a lot of work

In terms of operational use, it can be argued that the IME is just as simple as the MPD Operating Matrix. Plot a point or point your finger at the “post influx pressure” and influx volume combination and see if that point is in the “red” region or not.

Of course, trying to calculate an IME by arbitrarily specifying post influx pressure and volume in a modelling tool to try to find the combination that hits the limits (as explained earlier) is a lot of work. Luckily, there are purpose-built tools out there that does all of this, making the generation of an IME just as simple as filling out the textboxes in a MPD Operating Matrix.

For further reading on how this can be done, see:

Berg, G.A. Evjen, N. Velmurugan, M. Culen, The Influx-Management Envelope Considering Real-Fluid Behavior, SPE Drilling & Completion. (2020). https://doi.org/10.2118/198916-PA

Summing it up

MPD equipment can circulate out small influxes while maintaining constant bottomhole pressure. Due to the smaller pressure ratings and less rigorous testing regime on MPD equipment, a MPD Operating Matrix should be the bare minimum for any MPD operation.

Using an MPD Operating Matrix to decide whether to circulate out an influx through MPD equipment can have significant limitations.

As most MPD Operating Matrix’s fails to consider the required “pressure increase” when the influx gets closer to surface. Many influxes that would be considered “OK for MPD” in the Operating Matrix, will eventually have to be handed over to conventional well control.

Using an MPD Operating Matrix that has limits based on influx circulation calculations for a given well remedies this but leaves little room for circulating an influx with MPD equipment in many cases.

The Influx Management Envelope remedies a lot of these issues with the MPD Operating Matrix, but still maintains the same “look” as the MPD Operating Matrix, making it operationally as simple to use, although more complex to generate if not having a purpose-built tool for calculating it.

Is There a Doctor on the Rig? (CB explains: His PhD)

February 2, 2021We asked Christian Berg (CB) to give us some “behind the scenes” information about his PhD journey. Enjoy.

Drilling for oil and gas is a complex process, involving pumping of fluid through kilometers of fluid conduit, leading to wave propagation phenomena that becomes important at timescales relevant for automatic control. In my PhD work I have mainly focused on hydraulic modelling of drilling and has been supervised by Professor Bernt Lie and Adjunct Associate Professor Glenn-Ole Kaasa. The work has been funded as an Industrial PhD project by the Norwegian Research Council. The PhD project has taken place in the Telemark Modelling and Control Centre (TMCC) research group at USN, as well as at Kelda Dynamics.

New sensors for influx loss detection

Research on gas influxes, and their detection has surged after the Macondo incident. The design of kick detection and well control strategies require mathematical models of the same dynamics as control design for Managed Pressure Drilling (MPD). It can be said that in terms of kick detection, especially for conventional drilling, it is not the algorithms on how this can be done that is missing, but the sensors required for them. Prior to starting my PhD program, and through the work on the Thesis, a feasible alternative measurement principle has been studied, applicable to conventional drilling operations, using a subcritical venturi flume. A venturi flume is a critical-flow flume with a constricted flow which causes a sub to super critical flow transition. The upstream liquid level is correlated to the flow rate of the fluid. A venturi flume flow meter offers an accurate and economic alternative to return flowmeters currently used in the drilling industry. Three separate PhD theses have now been defended on the development of subcritical flumes for drilling fluid flow rate estimation in the research project SemiKID at the University of South-Eastern Norway, where Kelda has been a partner.

Running CFD analysis on a prototype venturi flume sensor design to evaluate how it behaves in a step from zero up to maximum flow.

Making Digital Twins

Through the work of my PhD, the topic of modelling, at different detail levels has been studied. This has been performed in parallel with the development of the Leidar MPD control system at Kelda Dynamics. For design and upgrades of the Leidar control system, extensive testing is performed on high-fidelity Partial Differential Equation (PDE) models capturing the dynamics of the drilling process. Development of these models and their validity is covered in multiple papers in my Thesis and has been a big part of the collaborative work in the HYDRA research project where Kelda has been a partner.

The control system developed by Kelda Dynamics through the last 6 years is based on the most commonly used simplified model and has been found to have good performance in real drilling operations for both single phase and multiphase cases. Perhaps one of the main success criteria in this has been the extensive testing of different solutions on the high-fidelity models coming from my work.

Christian with Sam, one of the drillers on Kelda’s first MPD Operation in the UAE. Not only was this our first job, but it was our first operation where the drillers were running constant bottom hole pressure control with hands off connections.

Managed Pressure Drilling: Influx handling

MPD opens a lot of possibilities when it comes to both detection of unwanted reservoir influx and circulating the influx out. MPD systems have less regulatory requirements and lower pressure ratings than conventional well control equipment. Due to this, performing what would normally be considered a well control operation using MPD equipment should be done with care. The Influx Management Envelope (IME) helps to deal with this. Although wanted by industry, little systematic description of the IME has existed in peer-reviewed journals until my work on describing the IME, demystifying, and deriving the IME from first principles, then discussing the implications of the different IME zones from an operational context.

“PhD on the rig”

Through my PhD work I have has spent 10 weeks on drilling rigs in Dubai, United Arab Emirates and Siberia in Russia, supporting setup and first time use cases of the Leidar Control System with high fidelity model testing of the control system in parallel. This has given valuable operational understanding outside of the “classroom” and these drilling operations are the topic of two of the Thesis papers. This has also given the rare opportunity of going from idea and prototype, to seeing the research in use and in person on actual drilling rigs, a privilege that few PhD students can claim to have experienced within the timespan of their PhD project.

Christian helping with rig up in Russia on Kelda’s first automated UBD operation. Here he is seen carrying the UPS to the dog house and proving to be a true Viking.

The full PhD thesis can be downloaded here: https://openarchive.usn.no/usn-xmlui/handle/11250/2646417?locale-attribute=en

Research collaboration in 2020

January 22, 2021

PROJECT 1: In-house industrial PhD on influx modelling”

- PhD #1: Christian Berg – Modelling for automatic control and estimation of influx and loss during drilling operations

PROJECT 2: “HYDRA – HYdraulics modelling for DRilling Automation”

- PhD #2: Mohammad Abbasi – Modeling and Order Reduction for Hydraulics Simulation in Managed Pressure Drilling

- PhD #3: Sajad Naderi Lordejani – Model reduction for infinite-dimensional systems, with application to managed pressure drilling

- PhD #4: Naveen Velmurugan – Distributed dynamics of influx during MPD operations; modelling and estimation

- PhD #5: Harshit Bansal – Structure-preserving model order reduction for drilling automation

From an early kick-off meeting of the HYDRA project in Porsgrunn, Norway: B.L: Linn, Ulf Jacob Aarsnes (IRIS), Prof. Will Schilders (TU/e), Prof. Nathan Van der Wouw (TU/e), Prof. Florent Di Meglio (Mines ParisTech), Glenn-Ole, Christian and Geir Arne. F.L: Harshit Bansal (TU/e), Mohammad Hossein Abbasi (TU/e), Jon Åge, Sajad Naderi Lordejani (TU/e) and Naveen Velmurugan (Mines ParisTech).

PROJECT 3: “Semi-KIDD – Sensors and models for improved kick/loss detection in drilling”

- PhD #6: Prasanna Welahettige: Transient drilling fluid flow in Venturi channels: comparing 3D and 1D models to experimental data

- PhD #7: Khim Chhantyal – Sensor Data Fusion based Modelling of Drilling Fluid Return Flow through Open Channels

- PhD #8: Asanthi Jinasena: Models and Estimators for Flow of Topside Drilling Fluid

- PhD #9: Haavard Holta – Kick & loss detection and estimation using distributed models

- PhD #10: Morten Hansen Jondahl – Data-driven Models for Estimation of Drilling Fluid Rheological Properties and Flow Rate

Name change

January 10, 2021“More than just controls.”

A new year brings new beginnings. We are pleased to announce that Kelda Drilling Controls will now be known as Kelda Dynamics.

“With the growth of Kelda over the past year, we felt that our company name should reflect the evolution of our products and services”, says Glenn-Ole Kaasa, CEO. “Leidar has grown from an industry-leading pressure controller, to include a hydraulics simulator for planning, a real-time hydraulics model for drilling process monitoring, enhanced influx-loss detection using cutting edge stochastic methods, contingency management, and much more to come in 2021. We have also adapted it for conventional drilling, so drillers can experience the benefits of Leidar on non-MPD hole sections as well.”

R&D is part of our DNA. We are always looking for better ways of doing things, and our engineers are involved in numerous development projects. For example, we are continuing our research on influx management to include dynamic influx tracking for safer and more efficient drilling.

“Kelda is more than just controls. Kelda is Dynamic.”

Christian Berg Ph.D.

August 3, 2020In the middle of COVID-19 restrictions, 20th of March 2020, our bright star Christian Berg had his public defense (disputation) and became the fifth Ph.D. in the Kelda team.

Congratulations! (Photo: Bernt Lie)

Doctoral thesis: Modeling for Automatic Control and Estimation of Influx and Loss During Drilling Operations

Click here to read the abstract or download the whole doctoral thesis.

Many, many hours of thinking, programming, simulations, analysis, re-doing, writing, and discussions have been used to produce this excellent doctoral thesis, and his in-depth knowledge, wide perspective, and practical understanding make this thesis even more interesting to read.

Other fun facts:

He is a husband, father of two, pilot, gamer, hunter, and did not take the ordinary path to become Ph.D., as he went from vocational education path over to the university and completing it with an industrial Ph.D.

Click here to read more about it.

Nominated for Gullkronen 2020

January 24, 2020Kelda Drilling Controls has been nominated for Gullkronen 2020 in the category for the “New Venture of the Year”, awarded by Rystad Energy.

Kelda was chosen as it has demonstrated exceptional achievement in one of the eight Gullkronen Awards categories, reflecting the program’s core values of innovation, success and ethics.

“We are truly honoured to be considered for the Gullkronen Awards by Rystad Energy” said Kelda’s Chief Executive Officer, Glenn-Ole Kaasa. “We’re humbled to be in the auspicious company of all nominees, some of which are InflowControl, Shell, Equinor, and Interwell” he continued. “The nomination alone is a testament to the vision, creativity and hard work of the entire Kelda team.”

Jarand Rystad, CEO of Rystad Energy, said: “The nominated companies are the most inspirational, successful and dynamic in the Norwegian energy space”. He continued: “They drive the Norwegian energy business and create jobs. The nominees are a benchmark of success for the rest of the Norwegian energy industry.”

Kelda will now have the chance to compete in one of the eight categories of this year’s Gullkronen competition. The awards ceremony will be held at Wallmanns Oslo on January 28.

Visit us at ADIPEC 2019

November 9, 2019Kelda will be joining the Norwegian Pavilion with Innowell Solutions, Trelleborg Offshore Norway, and CannSeal at ADIPEC 2019, Adu Dhabi.

Both our CEO, Glenn-Ole Kaasa and our CCO, Martin Culen will be attending from our side.

Find us at booth 9153

Martin Culen joins Kelda

November 6, 2019Kelda is pleased to announce that Martin Culen has joined the team as Chief Commercial Officer. He joined Kelda on October 1st, after 14 years with Blade Energy Partners.

Glenn-Ole Kaasa, CEO of Kelda stated “ Martin and I share the same vision for shaping MPD technology for the future, and I am truly happy to have him onboard as our CCO. Martin is one of the leading authorities on MPD and UBD in the industry and will be instrumental for what we are trying to achieve with Kelda going forward. “

Martin brings 25 years of industry experience to Kelda, all from a foundation of Underbalanced and Managed Pressure Drilling. He started his professional career in Canada drilling Coiled Tubing Underbalanced wells prior to moving overseas executing UBD projects in the North Sea and Oman. During his time with Blade, Martin participated in countless projects globally over the years, and held the position of Director for Blade in Dubai.

In addition, Martin’s contribution to the industry includes the development of the Well Controllability Curve (along with Robert Graham) for UBD wells and the introduction of the Influx Management Envelope for MPD operations. He also remains a staunch contributor to industry groups such as the IADC and SPE.

“ When I first was introduced to Kelda’s vision for the future of MPD systems, I knew I had found a kindred spirit ”, Martin says, “ I’m excited to join a truly creative and gifted team. I am looking forward to the positive impact Kelda is going to make on the energy industry.”

Joining Innovation Norway Global Growth US/Mexico Energy Program

October 17, 2019Innovation Norway is running a program to get Norwegian technology companies into the US and Mexico Energy market. Kelda Drilling Controls will join this program for 2019 and 2020 and are excited to deliver more state-of-the-art technology into the region.

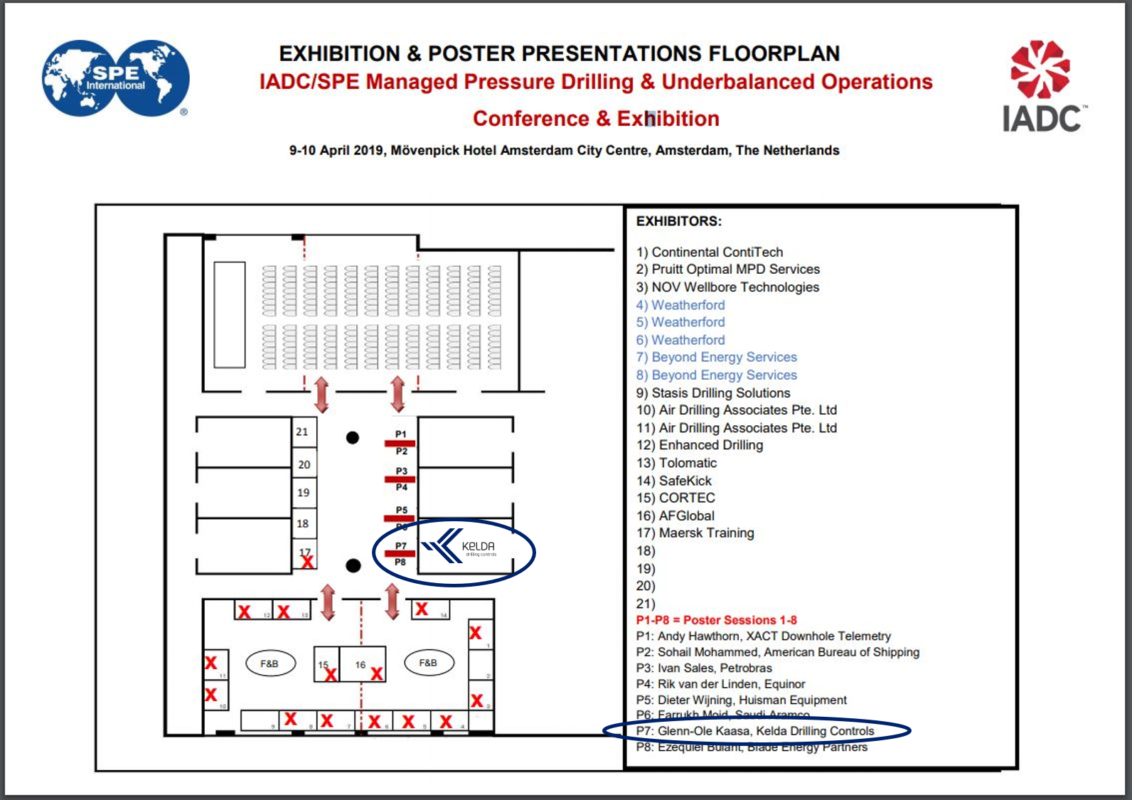

Meet Kelda here: IADC/SPE Managed Pressure Drilling & Underbalanced Operations Conference and Exhibition

March 11, 2019Kelda will have a poster presentation at the IADC/SPE Managed Pressure Drilling & Underbalanced Operations Conference in Amsterdam 9-10 April 2019. The conference will take place in the Mövenpick hotel in downtown Amsterdam, and Kelda will have a poster session on automated pressure control for underbalanced drilling – be sure to pay us a visit at P7 as shown on the floorplan below:

Our presentation is titled: “Automated Pressure Control for UBD Operations; Benchmark Testing and Field Validation“, which will showcase the results from several field case studies from the application of automated pressure control to a series of underbalanced drilling (UBD) operations in Russia. An overview of the encountered challenges in MPD/UBD operations is outlined and related to functional requirements for pressure control in MPD operations.

To see the full program and read more about the conference, please visit the IADC website: IADC/SPE Managed Pressure Drilling & Underbalanced Operations Conference & Exhibition (external link)

Archive

- SPE/IADC MPD & UBO 2022 Conference & Exhibition September 26, 2022

- RT-IME shown at Gibson Reports August 13, 2021

- Join us on the Gibson Reports MPD Event June 12, 2021

- First milestone of R&D project supported by Innovation Norway June 4, 2021

- Aberdeen Drilling School to Exclusively Use Kelda’s Hydraulic Engine March 25, 2021

- CB explains: The IME approach to handling influxes with MPD March 12, 2021

- Is There a Doctor on the Rig? (CB explains: His PhD) February 2, 2021

- Research collaboration in 2020 January 22, 2021

- Name change January 10, 2021

- Christian Berg Ph.D. August 3, 2020

- Nominated for Gullkronen 2020 January 24, 2020

- Visit us at ADIPEC 2019 November 9, 2019

- Martin Culen joins Kelda November 6, 2019

- Joining Innovation Norway Global Growth US/Mexico Energy Program October 17, 2019

- Meet Kelda here: IADC/SPE Managed Pressure Drilling & Underbalanced Operations Conference and Exhibition March 11, 2019

- Kevin Wise elected to the U.S. National Academy of Engineering November 7, 2018

- Kelda joins the Industry Master-programme September 19, 2018

- First automated UBD operation in Russia July 4, 2018

- Completed offshore drilling in Indonesia April 18, 2018

- Kelda Products (Kelda inside) April 10, 2018

- Funding from Oslofjordfondet April 9, 2018

- Another job, another success July 24, 2017

- Kevin Wise receives IEEE. Technical Excellence in Aerospace Control Award December 25, 2016

- Article in Teknamagasinet December 5, 2016

- Kickoff Workshop Industrial PhD Project October 24, 2016

- First MPD system operated by driller September 26, 2016

- Research Project Startup at HSN September 21, 2016

- MPD Conference in Galveston April 11, 2016

- Successfull flow loop testing March 25, 2016

- Visit us at Al Mansoori’s stand at ADIPEC November 9, 2015

- Glenn-Ole Kaasa speaker at SPE MPD workshop in Rio August 14, 2015

- New R&D Engineer: Vinicius de Oliveira June 1, 2015

- DrillingContractor.org article with Kevin Wise May 1, 2015

- Kevin Wise presented at the MPD/UBO Conference April 21, 2015

- Industrial PhD funding granted November 1, 2014

- New Research Engineer: Jon Åge Stakvik June 28, 2014

- New Research Engineer: Christian Berg June 10, 2014

- New Leading Expert: Pål Jacob Nessjøen April 1, 2014

- Research grant from Oslofjordfondet March 27, 2014

- Support granted from Innovasjon Norge March 12, 2014

- New Leading Expert: Geir Arne Evjen March 1, 2014

- New Chief Advisor: Robert Graham January 10, 2014

- New Chief Advisor: Kevin Wise January 10, 2014

- Kelda Drilling Controls Established October 15, 2013