We asked Christian Berg (CB) to give us some “behind the scenes” information about his PhD journey. Enjoy.

Drilling for oil and gas is a complex process, involving pumping of fluid through kilometers of fluid conduit, leading to wave propagation phenomena that becomes important at timescales relevant for automatic control. In my PhD work I have mainly focused on hydraulic modelling of drilling and has been supervised by Professor Bernt Lie and Adjunct Associate Professor Glenn-Ole Kaasa. The work has been funded as an Industrial PhD project by the Norwegian Research Council. The PhD project has taken place in the Telemark Modelling and Control Centre (TMCC) research group at USN, as well as at Kelda Dynamics.

New sensors for influx loss detection

Research on gas influxes, and their detection has surged after the Macondo incident. The design of kick detection and well control strategies require mathematical models of the same dynamics as control design for Managed Pressure Drilling (MPD). It can be said that in terms of kick detection, especially for conventional drilling, it is not the algorithms on how this can be done that is missing, but the sensors required for them. Prior to starting my PhD program, and through the work on the Thesis, a feasible alternative measurement principle has been studied, applicable to conventional drilling operations, using a subcritical venturi flume. A venturi flume is a critical-flow flume with a constricted flow which causes a sub to super critical flow transition. The upstream liquid level is correlated to the flow rate of the fluid. A venturi flume flow meter offers an accurate and economic alternative to return flowmeters currently used in the drilling industry. Three separate PhD theses have now been defended on the development of subcritical flumes for drilling fluid flow rate estimation in the research project SemiKID at the University of South-Eastern Norway, where Kelda has been a partner.

Running CFD analysis on a prototype venturi flume sensor design to evaluate how it behaves in a step from zero up to maximum flow.

Making Digital Twins

Through the work of my PhD, the topic of modelling, at different detail levels has been studied. This has been performed in parallel with the development of the Leidar MPD control system at Kelda Dynamics. For design and upgrades of the Leidar control system, extensive testing is performed on high-fidelity Partial Differential Equation (PDE) models capturing the dynamics of the drilling process. Development of these models and their validity is covered in multiple papers in my Thesis and has been a big part of the collaborative work in the HYDRA research project where Kelda has been a partner.

The control system developed by Kelda Dynamics through the last 6 years is based on the most commonly used simplified model and has been found to have good performance in real drilling operations for both single phase and multiphase cases. Perhaps one of the main success criteria in this has been the extensive testing of different solutions on the high-fidelity models coming from my work.

Christian with Sam, one of the drillers on Kelda’s first MPD Operation in the UAE. Not only was this our first job, but it was our first operation where the drillers were running constant bottom hole pressure control with hands off connections.

Managed Pressure Drilling: Influx handling

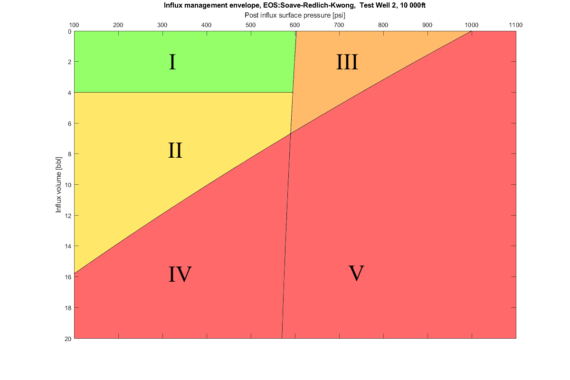

MPD opens a lot of possibilities when it comes to both detection of unwanted reservoir influx and circulating the influx out. MPD systems have less regulatory requirements and lower pressure ratings than conventional well control equipment. Due to this, performing what would normally be considered a well control operation using MPD equipment should be done with care. The Influx Management Envelope (IME) helps to deal with this. Although wanted by industry, little systematic description of the IME has existed in peer-reviewed journals until my work on describing the IME, demystifying, and deriving the IME from first principles, then discussing the implications of the different IME zones from an operational context.

“PhD on the rig”

Through my PhD work I have has spent 10 weeks on drilling rigs in Dubai, United Arab Emirates and Siberia in Russia, supporting setup and first time use cases of the Leidar Control System with high fidelity model testing of the control system in parallel. This has given valuable operational understanding outside of the “classroom” and these drilling operations are the topic of two of the Thesis papers. This has also given the rare opportunity of going from idea and prototype, to seeing the research in use and in person on actual drilling rigs, a privilege that few PhD students can claim to have experienced within the timespan of their PhD project.

Christian helping with rig up in Russia on Kelda’s first automated UBD operation. Here he is seen carrying the UPS to the dog house and proving to be a true Viking.

The full PhD thesis can be downloaded here: https://openarchive.usn.no/usn-xmlui/handle/11250/2646417?locale-attribute=en