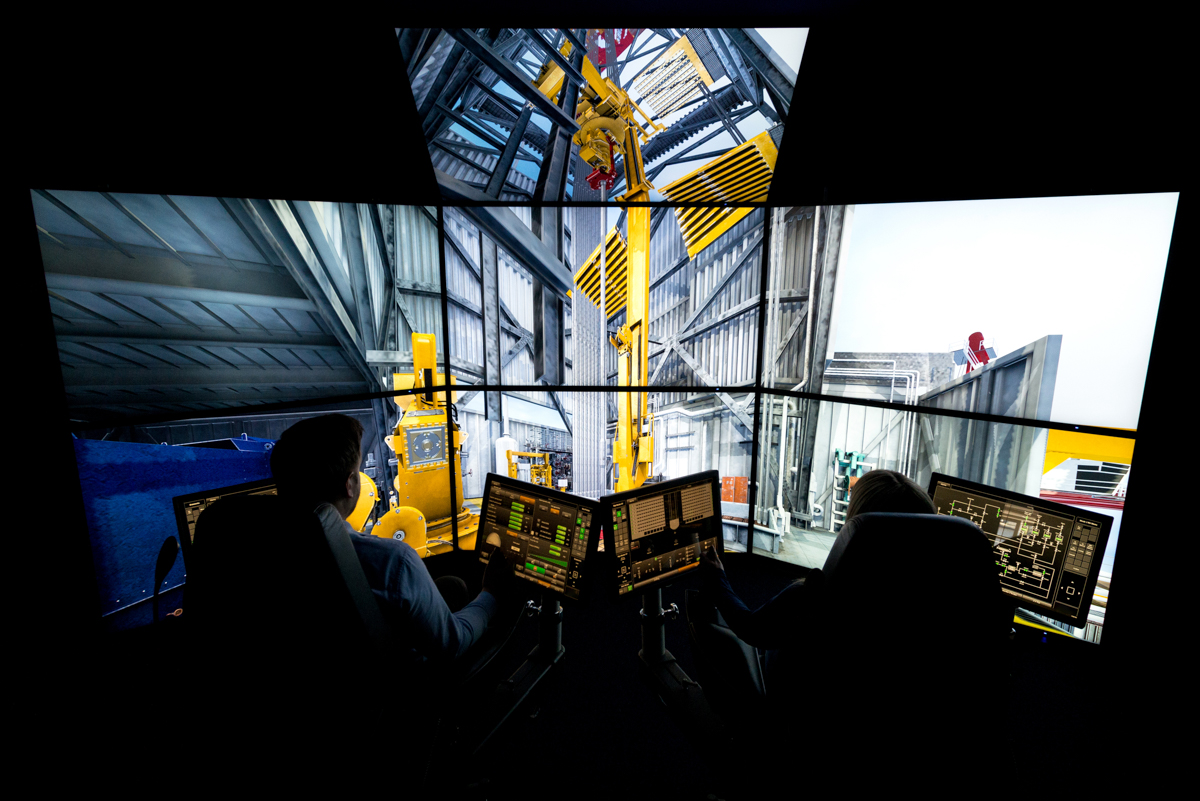

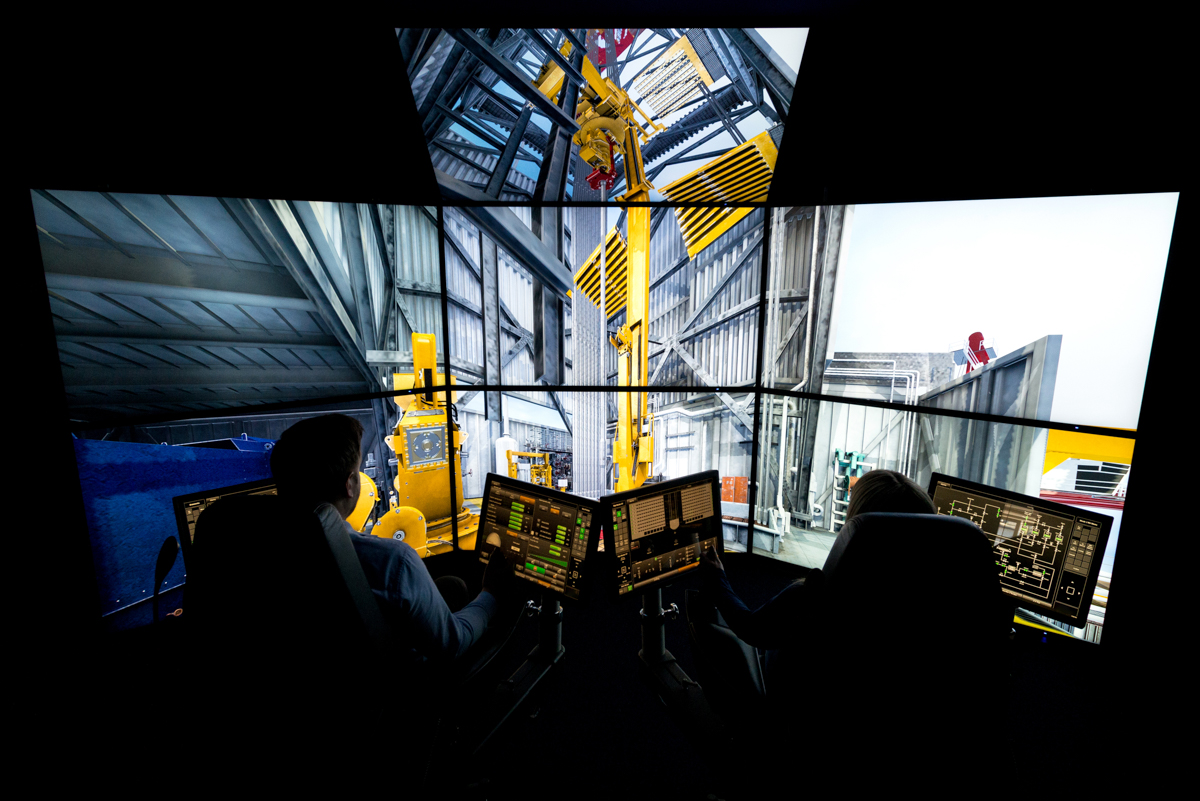

Aberdeen Drilling School (ADS) and Kelda Dynamics have entered into an agreement whereby Kelda’s dynamic hydraulic engine will be used exclusively in ADS drilling and well control simulators.

“We have been using Kelda’s multiphase hydraulics engine in our advanced training simulators in Oiltec since 2016, and have been very happy with its performance and reliability. Kelda’s shared vision for cloud-based solutions fits very well with our plans to provide cloud-based training to our international clients. ” said, Jason Grant, Managing Director of ADS.

Glenn-Ole Kaasa, CEO of Kelda, adds ” We are very pleased to be working with ADS on their new initiatives. It’s an honor to be chosen as exclusive supplier to a world-renowned training organization. The ADS team is very forward thinking and we’re excited to be working with them. It’s extremely rewarding to experience how the drilling industry now adapts our technology further, to improve drilling efficiency and enhance operational safety.”

The hydraulic simulator engine will be rolled out to ADS and RelyOn training centers around the globe as well as planned cloud-based training courses.

Aberdeen Drilling School Ltd, part of the RelyOn Nutec group and globally recognized for its advanced drilling, well engineering and well control training. From our RelyOn Nutec Copenhagen headquarter and 33 sites around the world, we serve +10,000 companies every year, from the sole employee contractor to some of the biggest companies in the high-risk industries across the world.

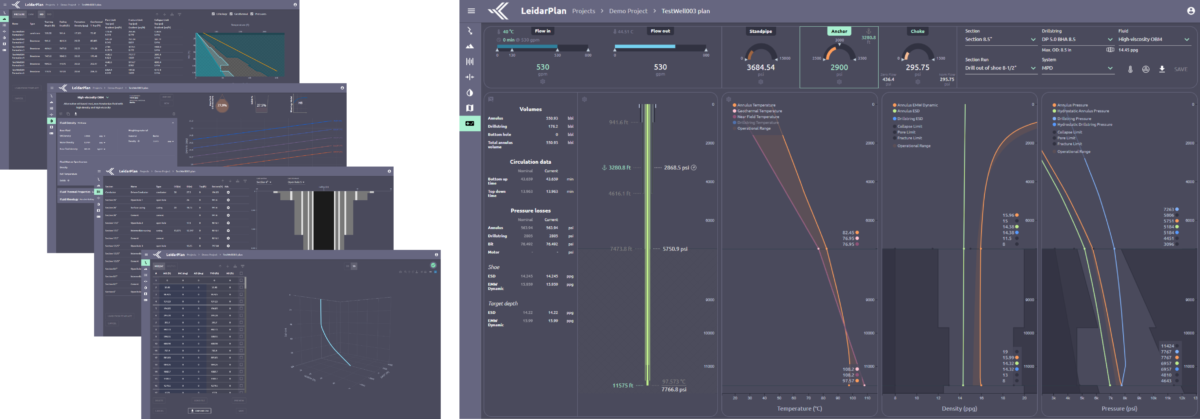

Kelda Dynamics has a unique competence in drilling technology, delivering fit-for-purpose solutions for the drilling industry. Our dynamic hydraulic model is a core element of our expertise and of many Kelda’s market leading technology products. It is being continuously developed, based on new research, data from newly drilled wells and feedback from customers.

Contact for further information:

Jason Grant: jgrant@aberdeendrilling.com

Martin Culen: martin@kelda.no